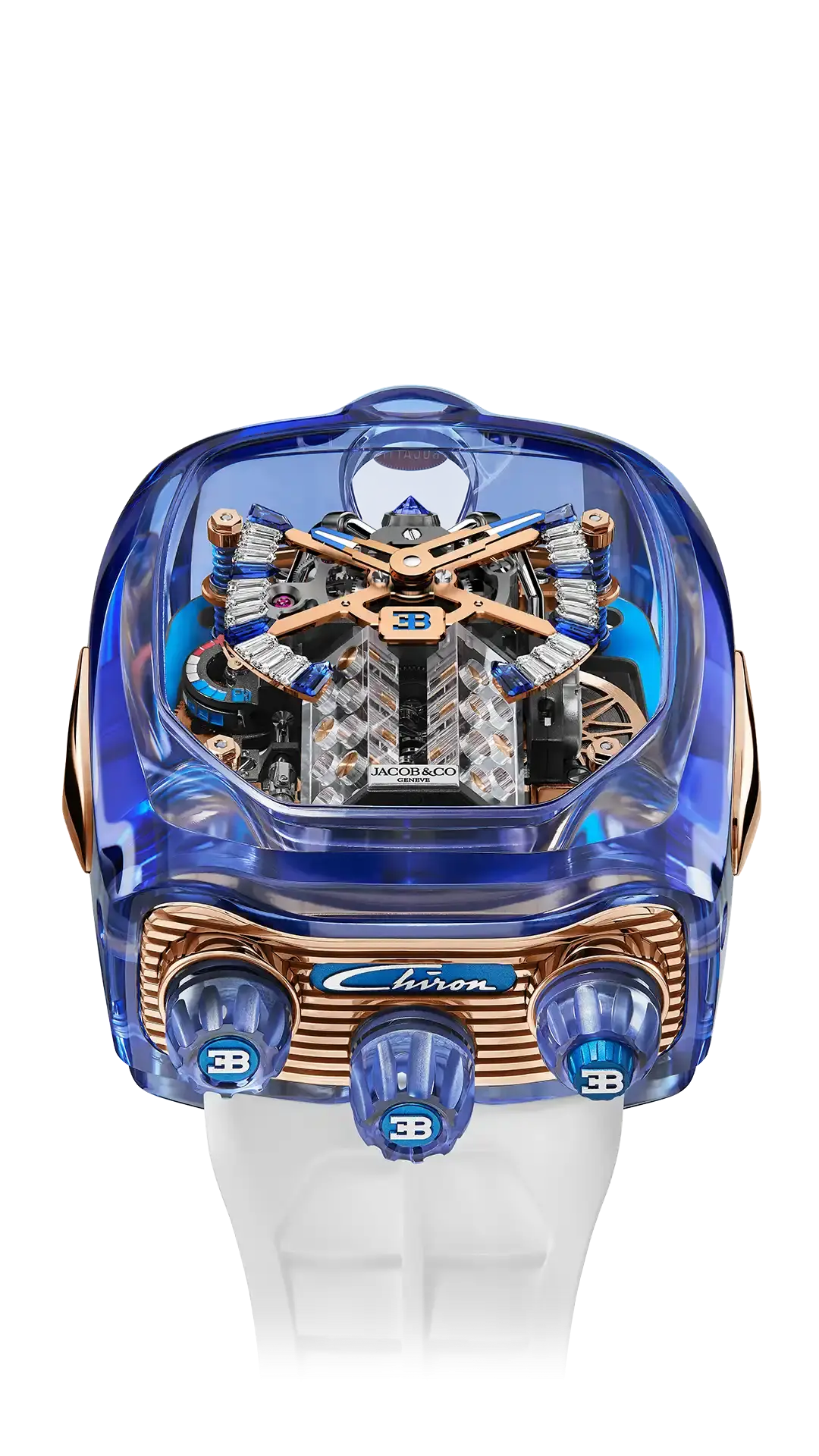

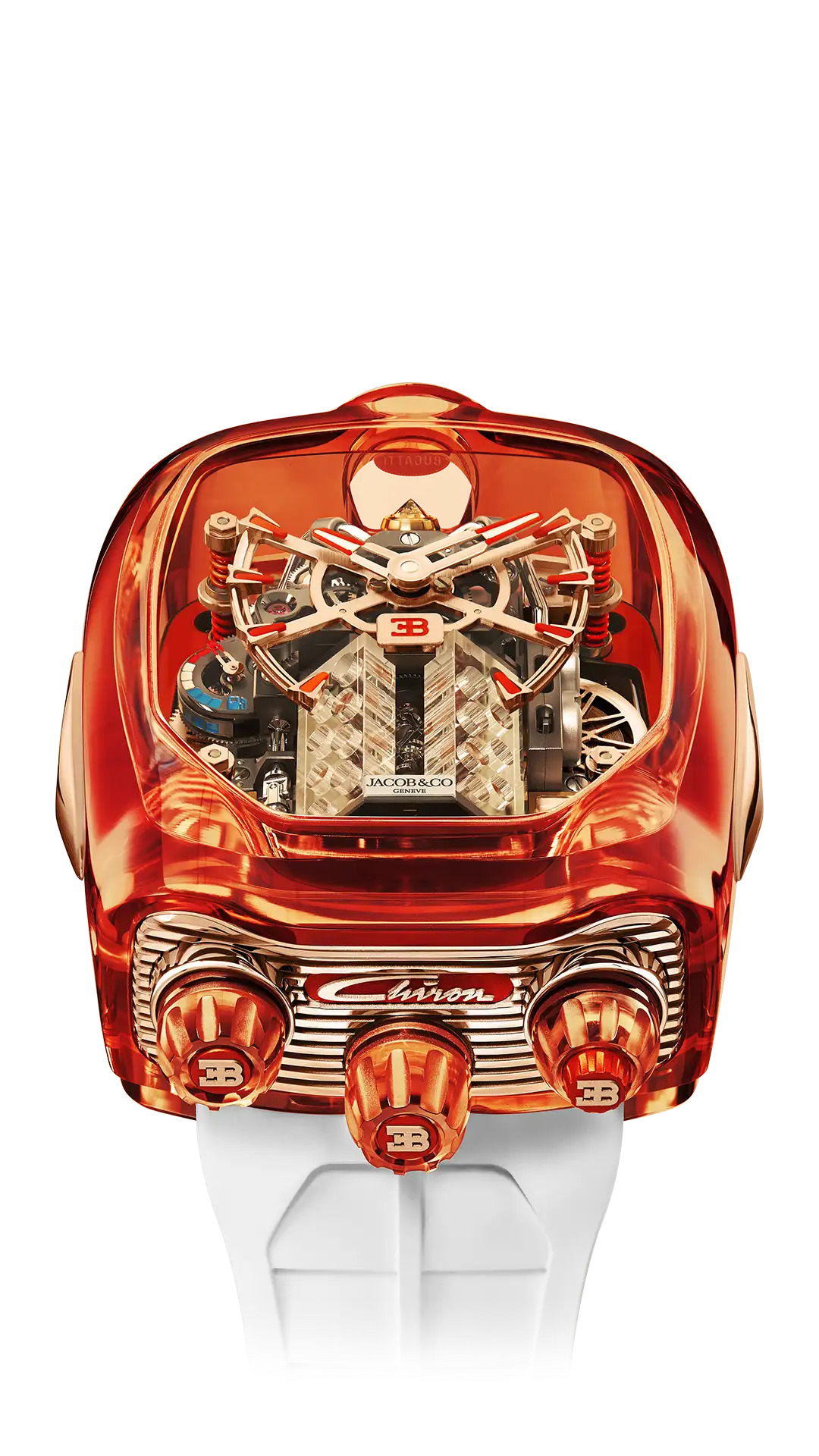

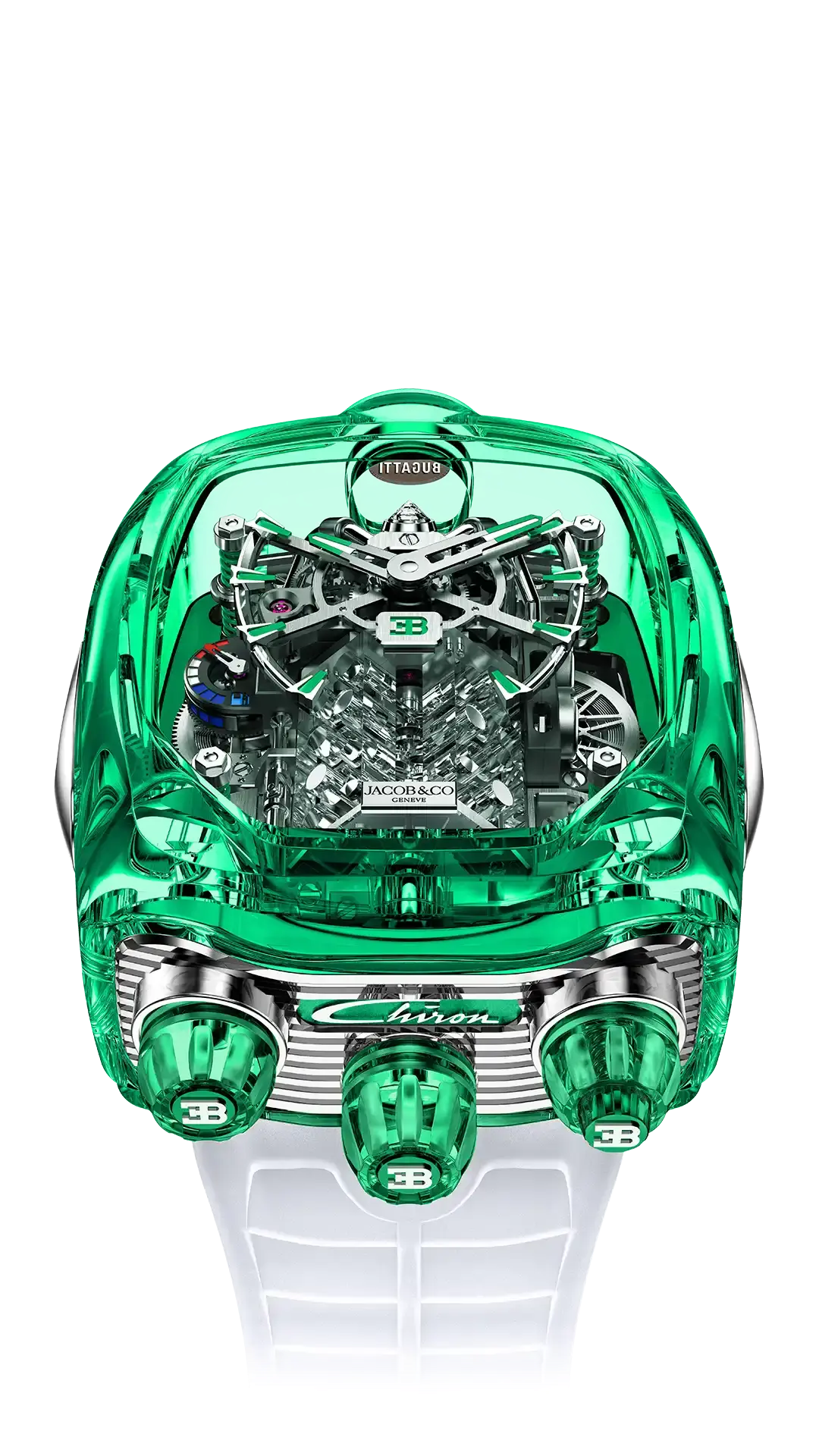

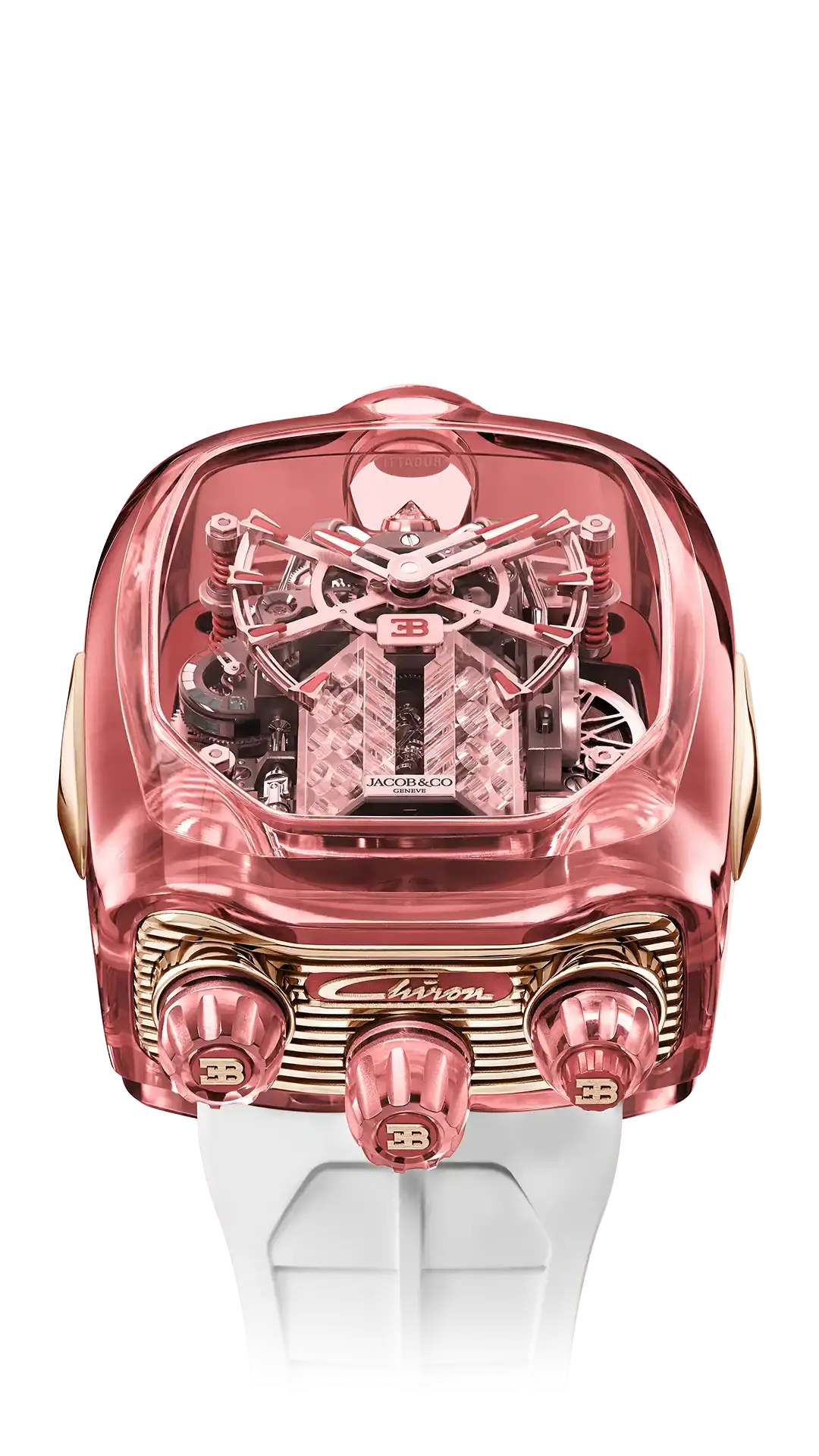

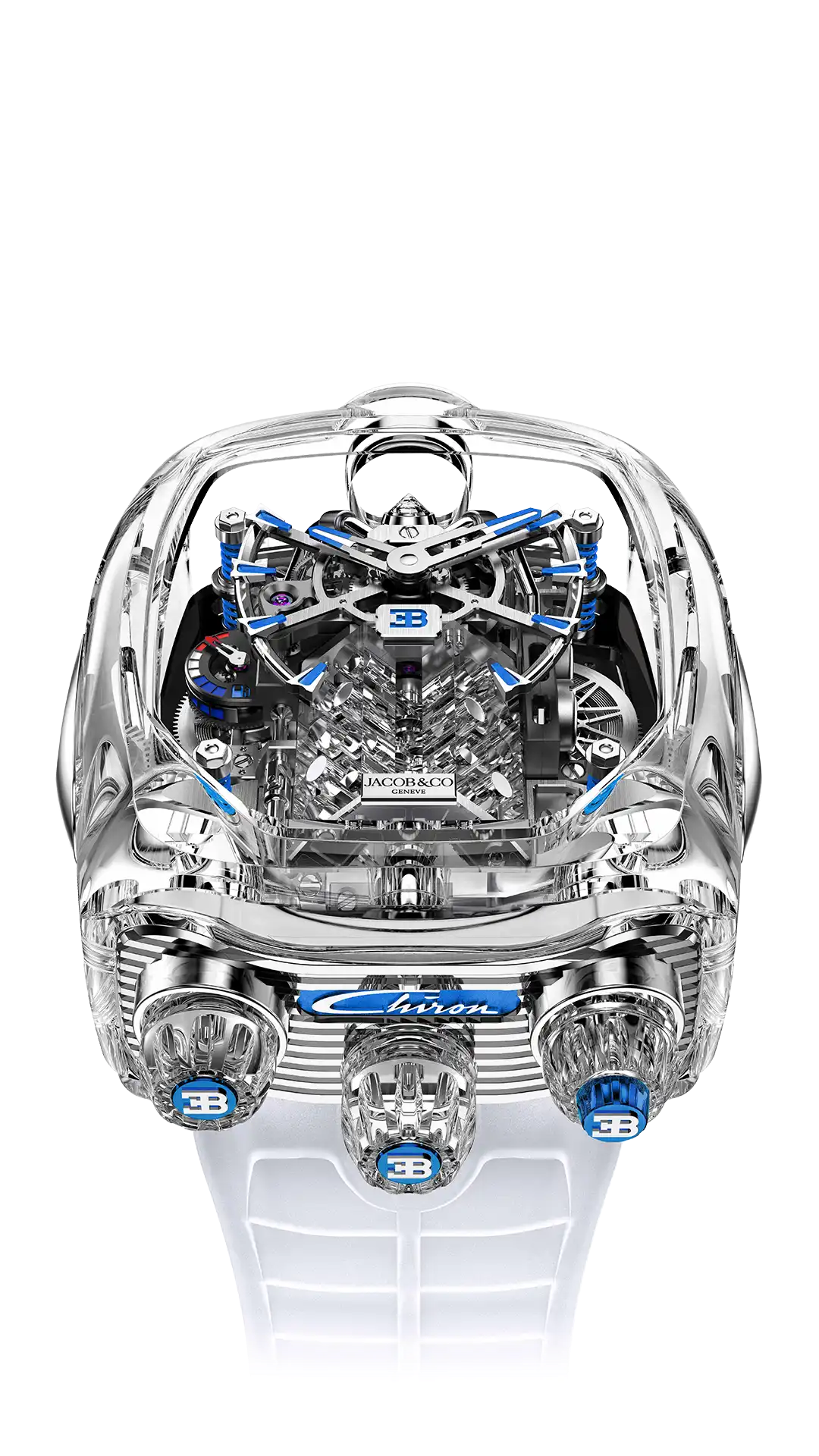

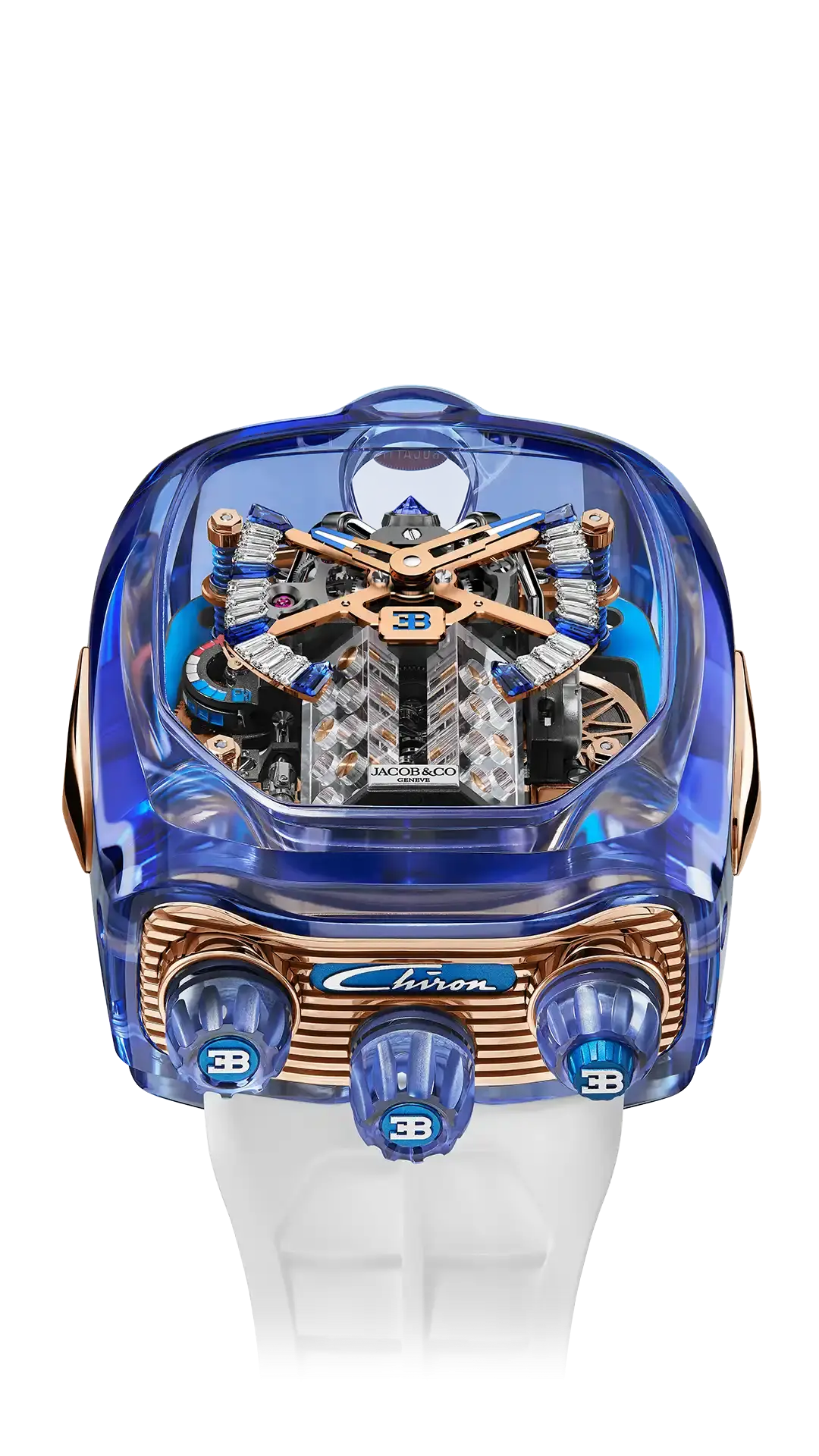

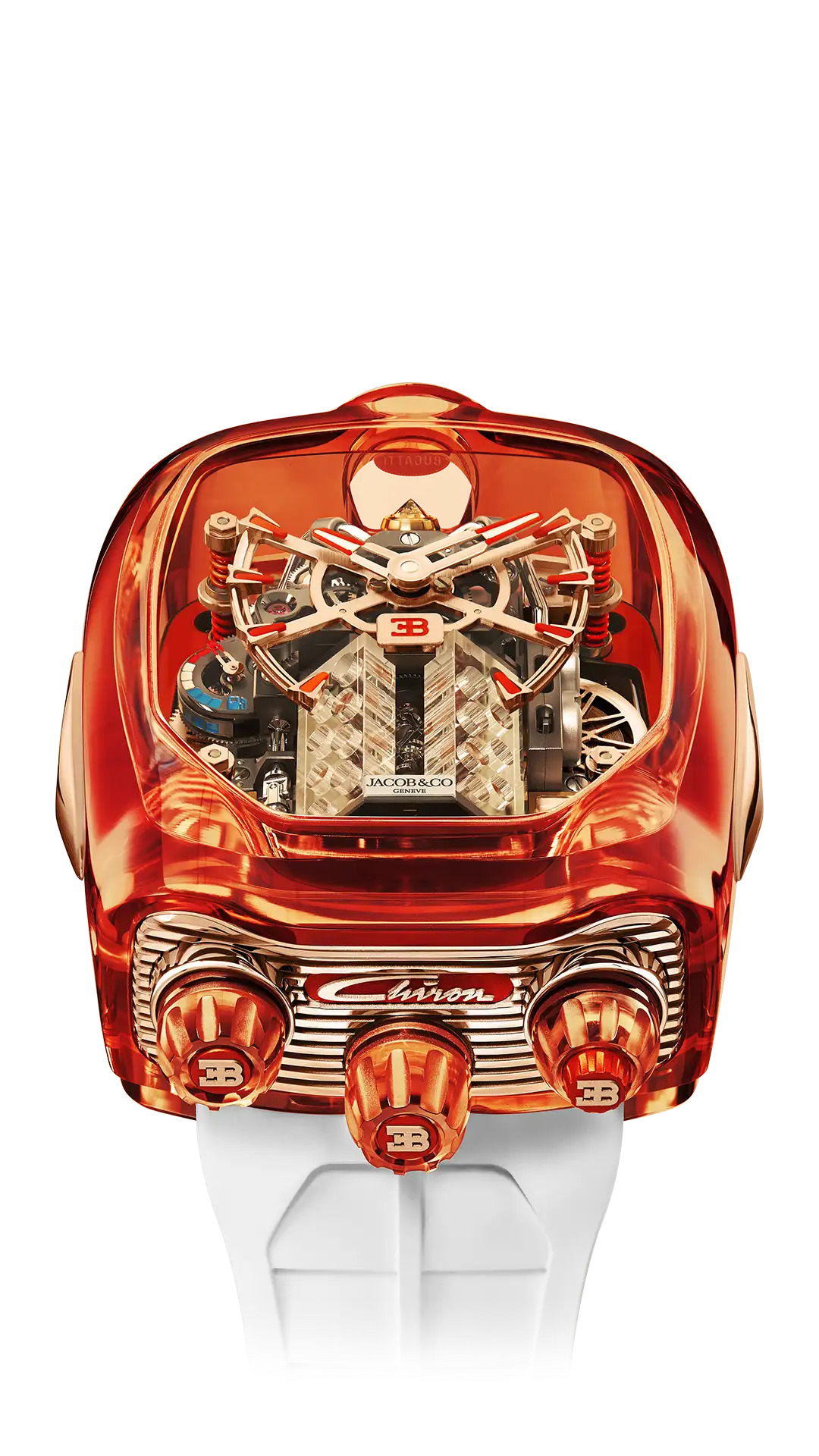

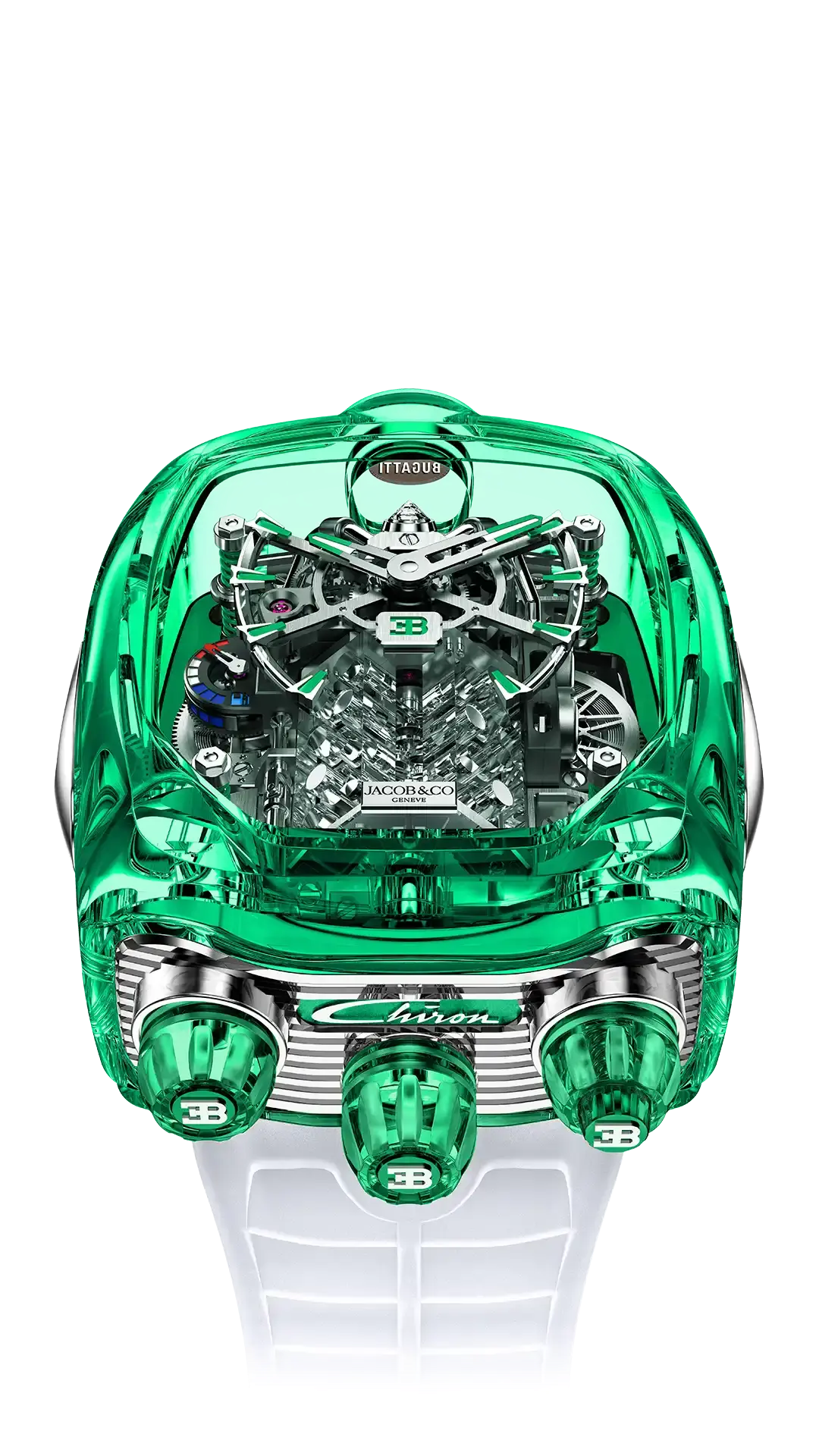

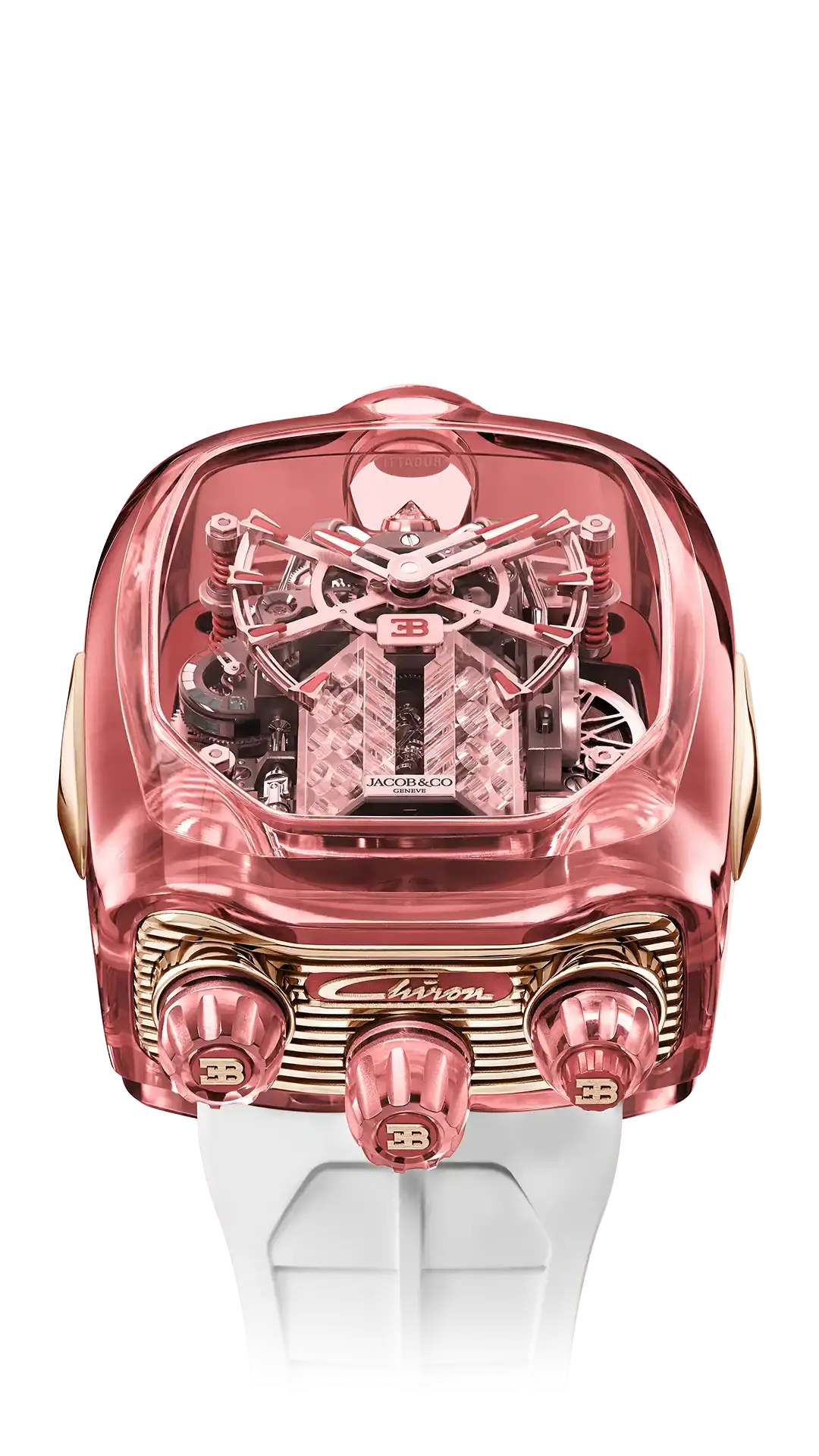

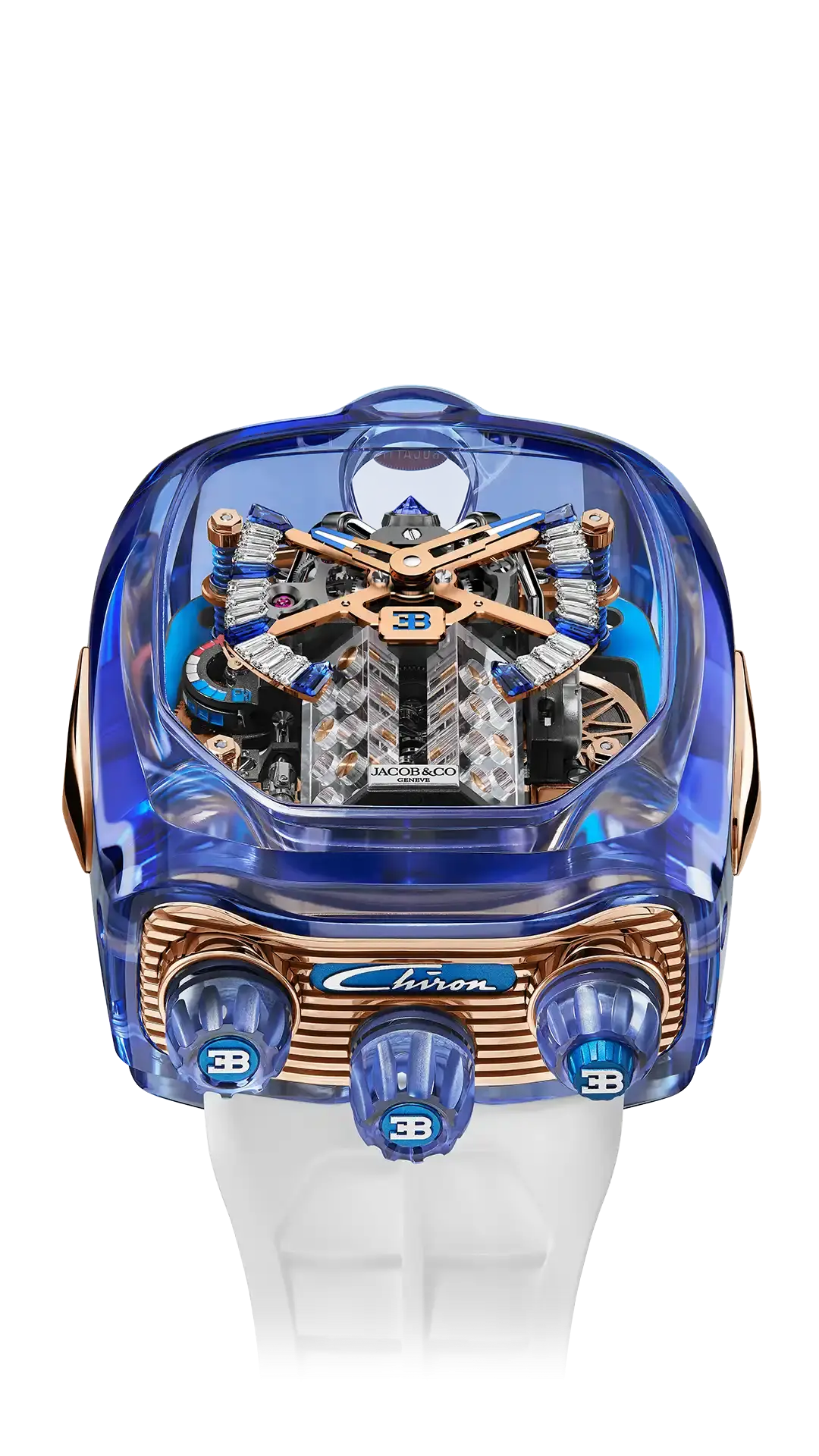

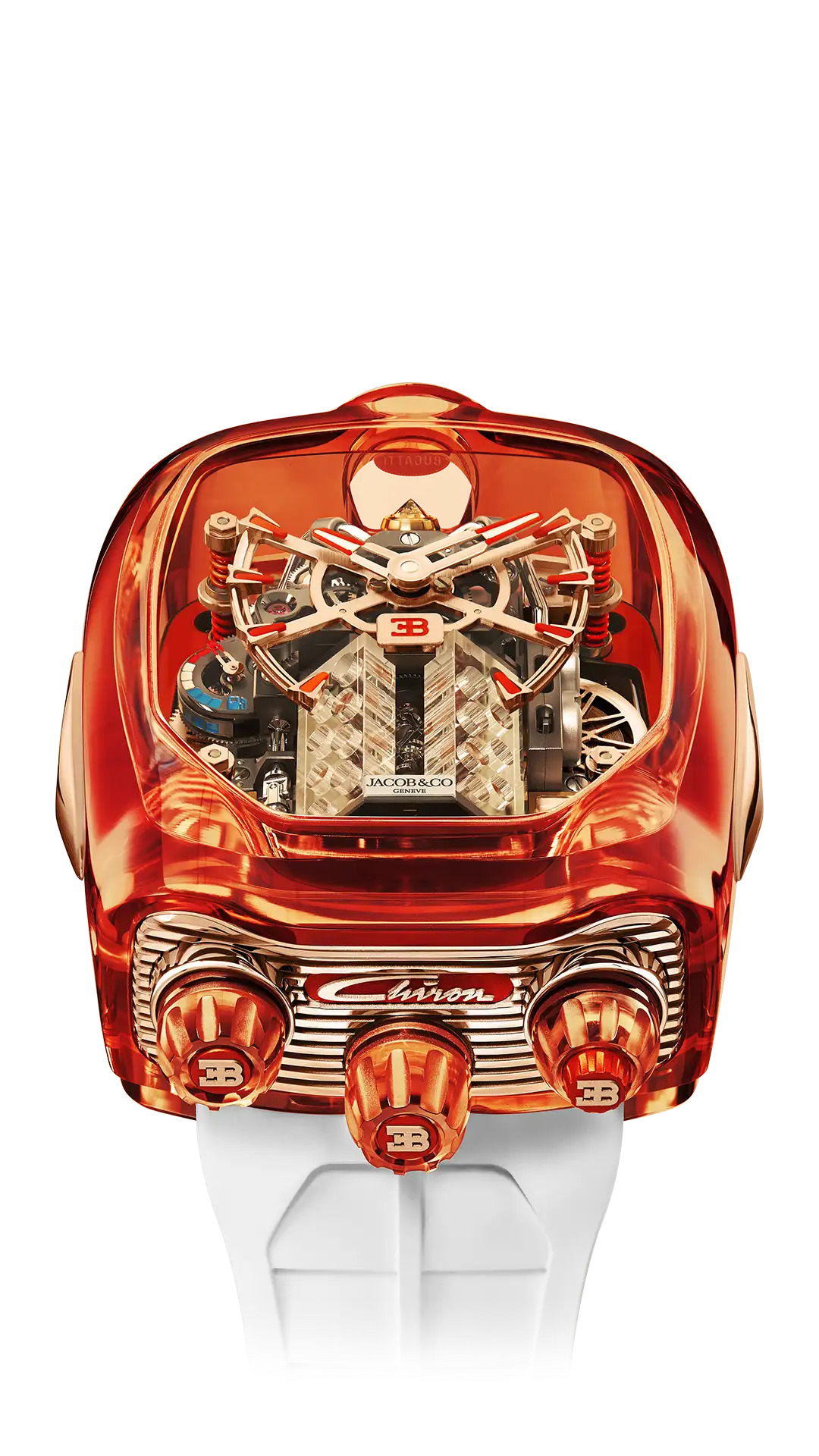

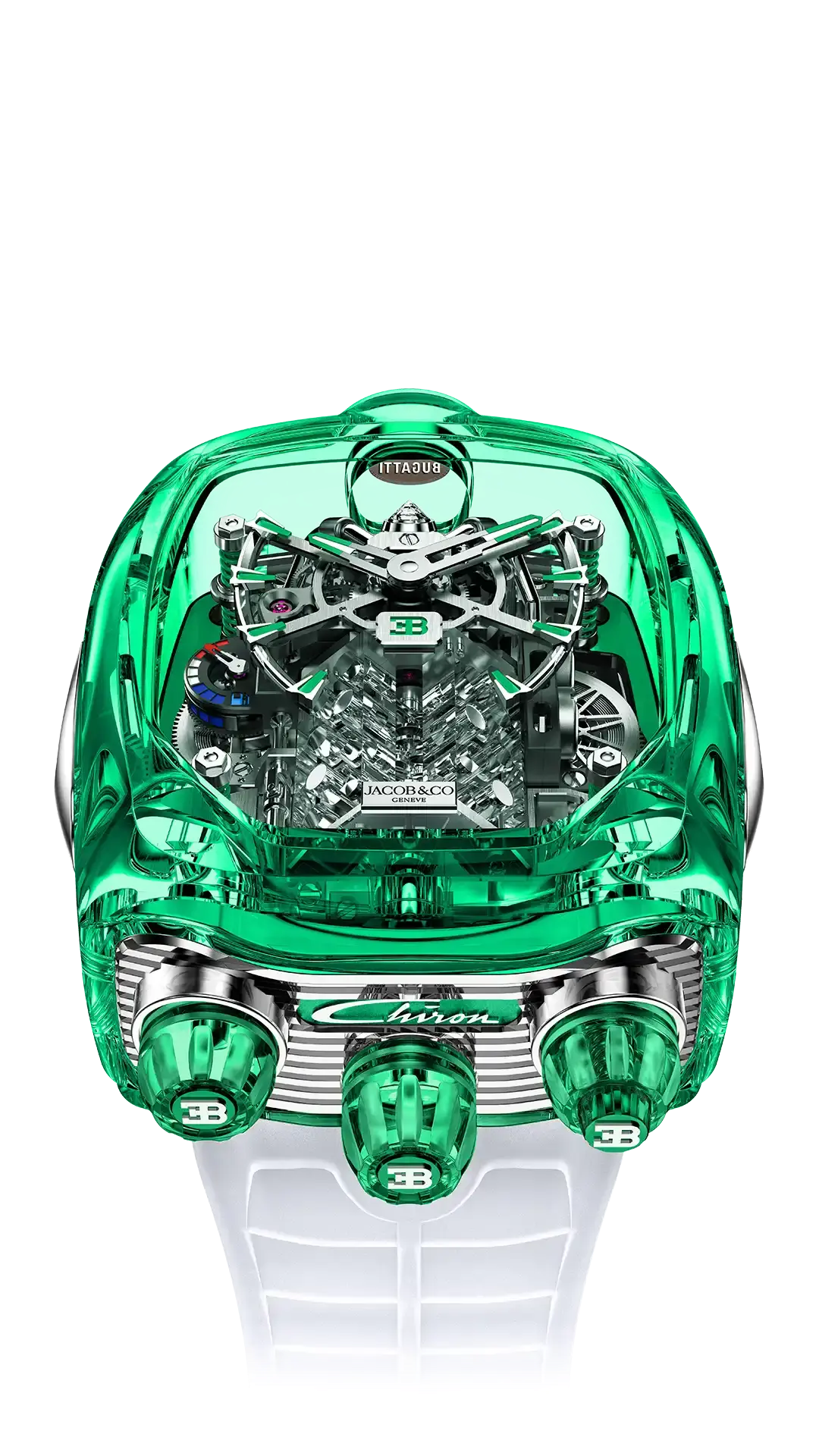

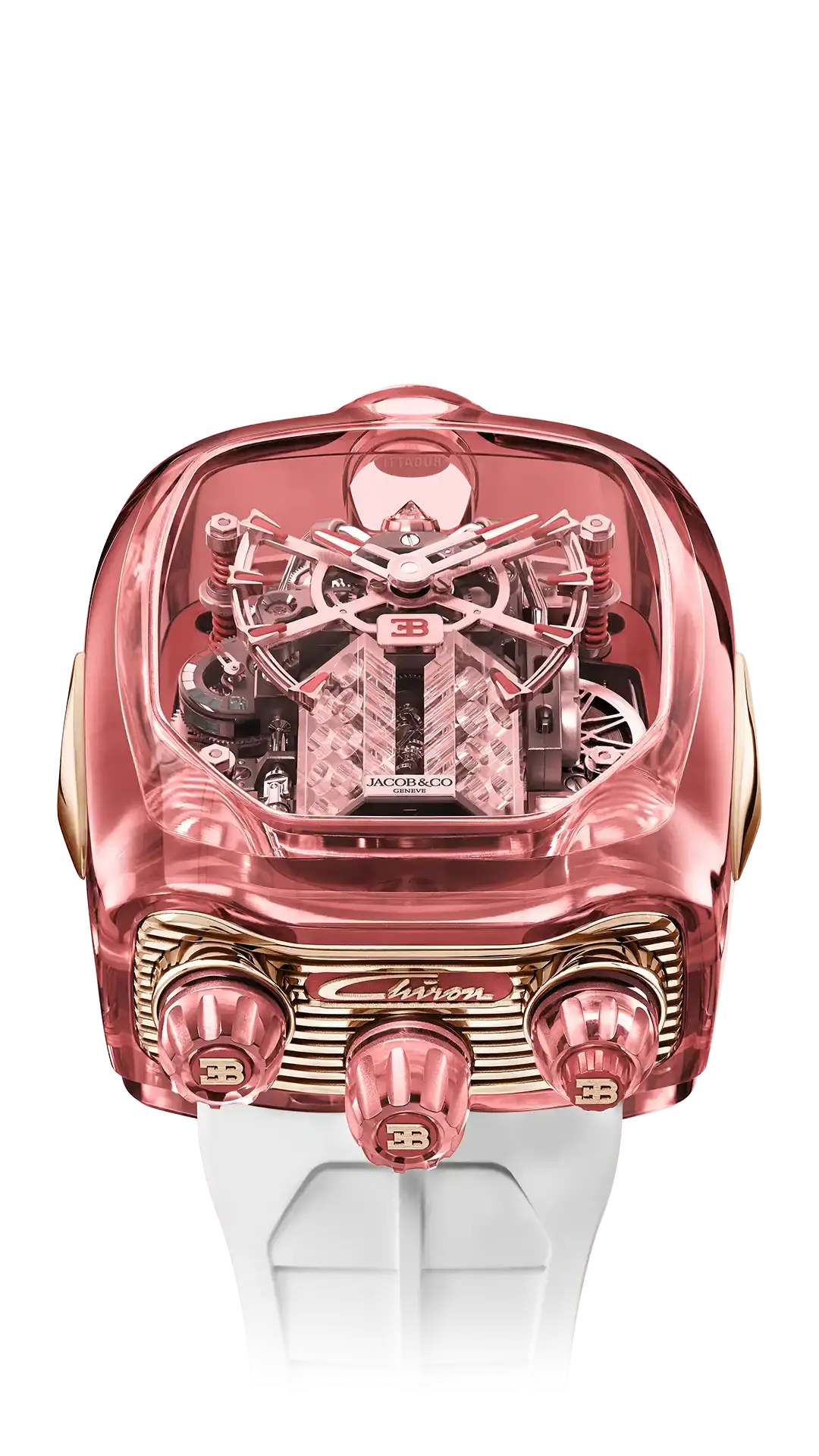

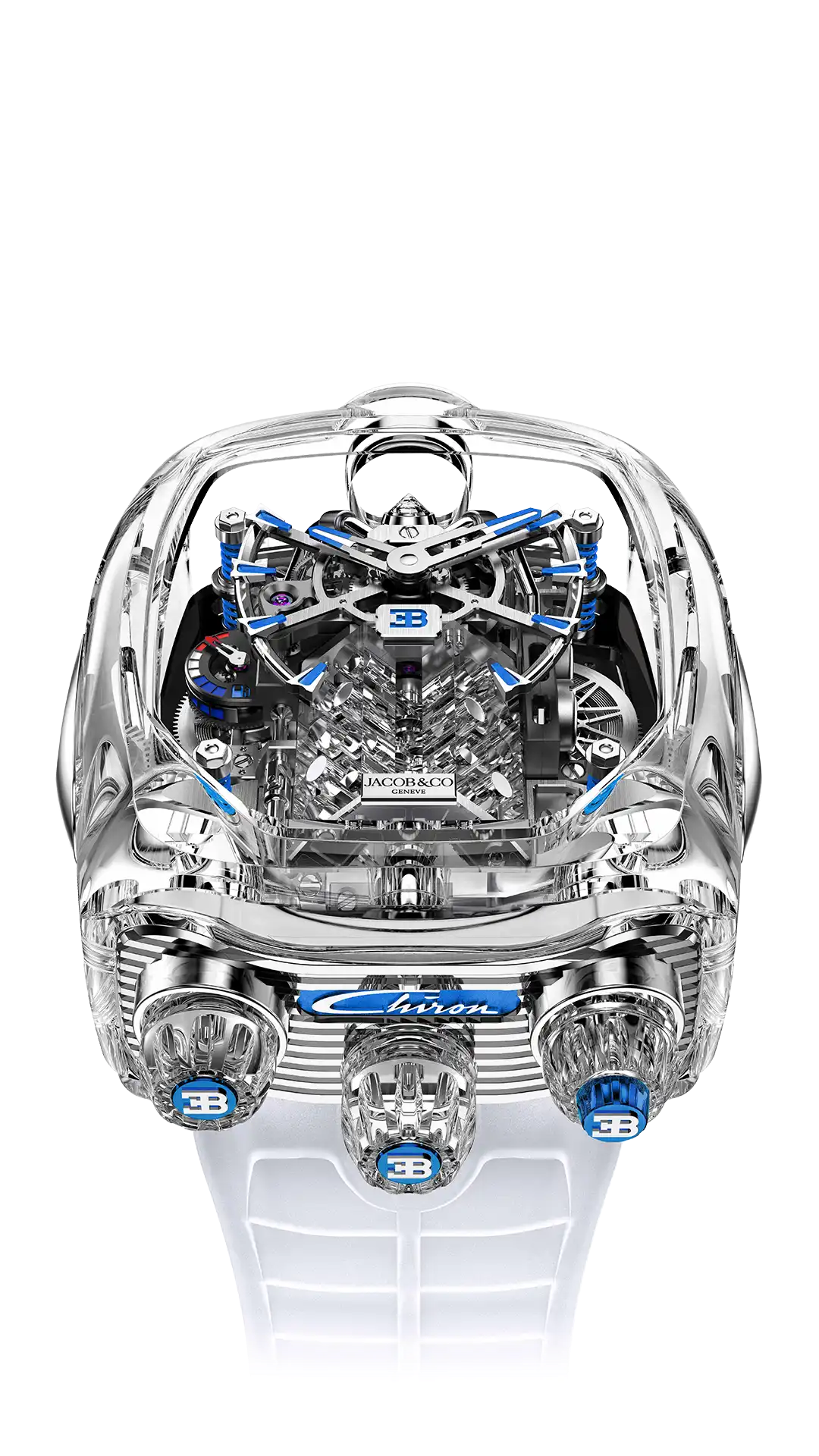

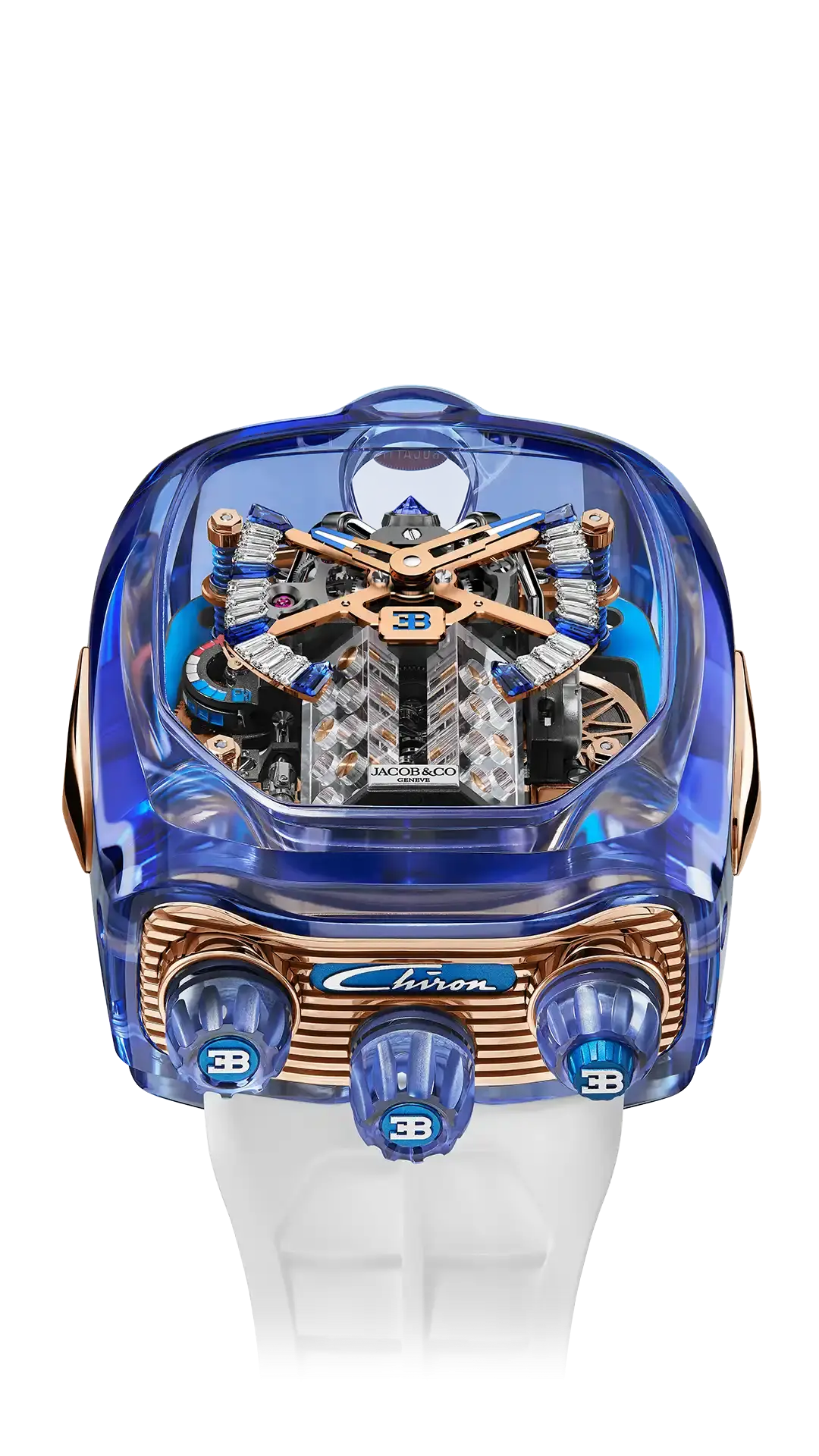

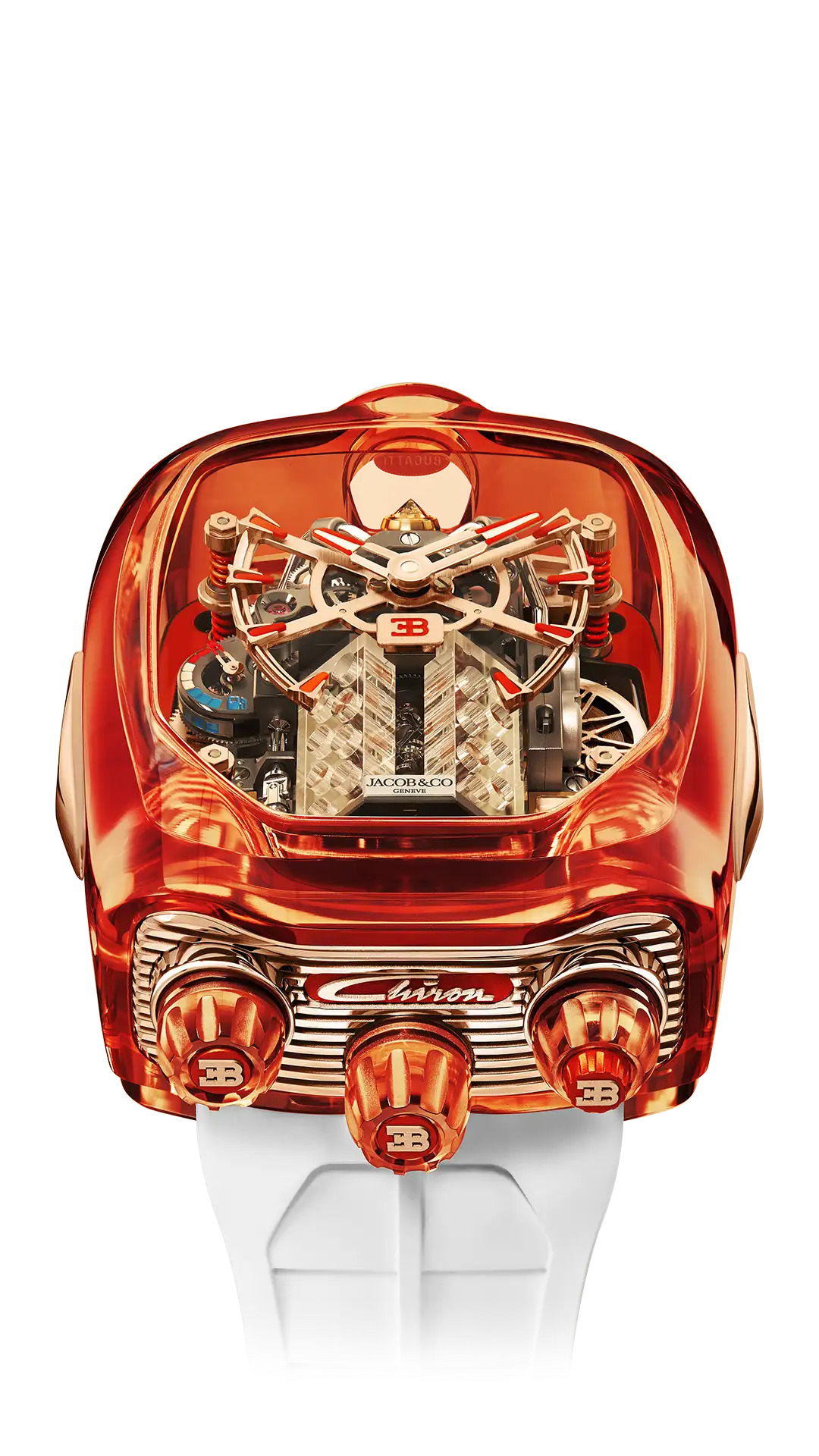

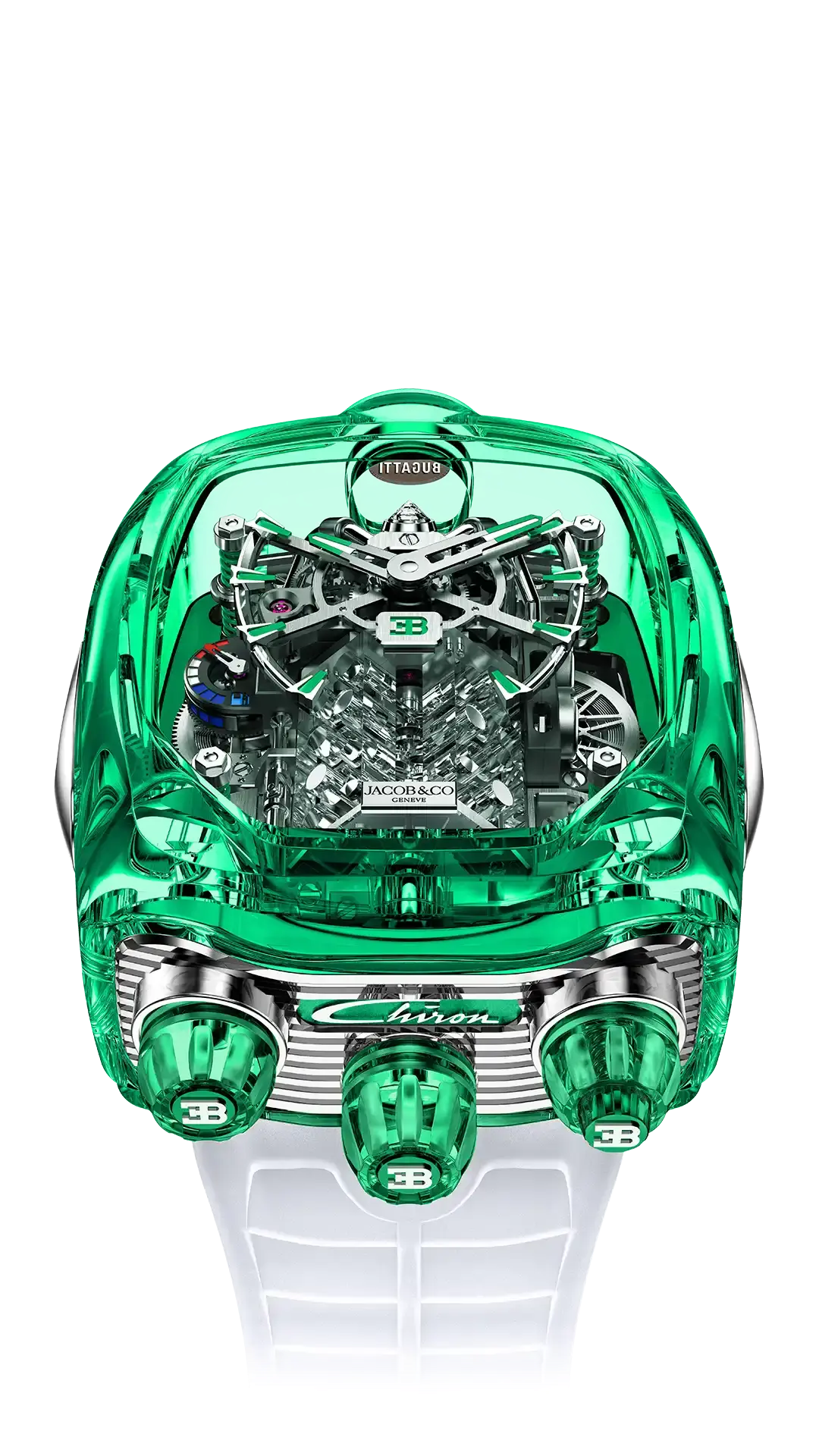

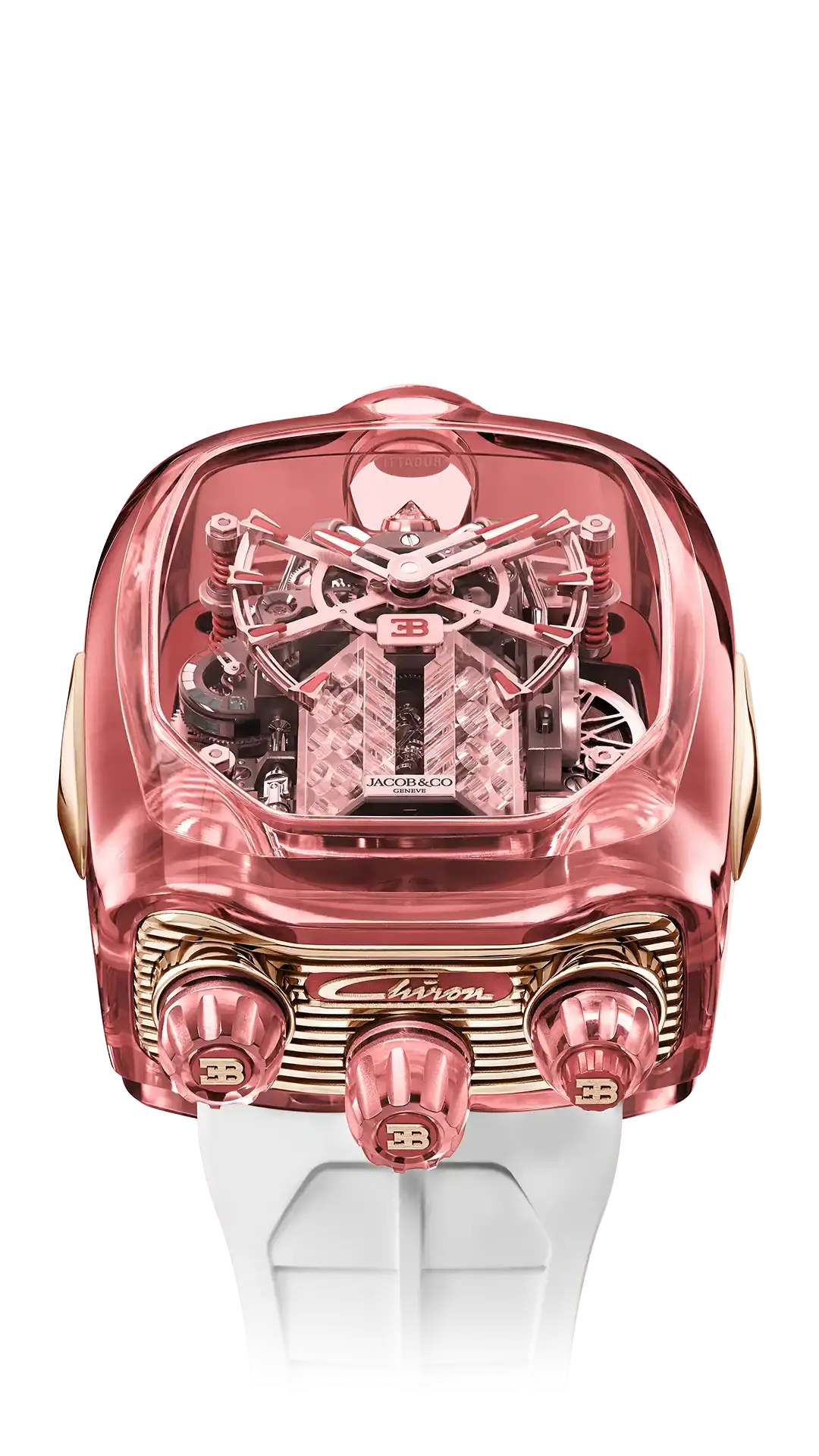

BUGATTI CHIRON TOURBILLON SAPPHIRE CRYSTAL

Clear

I

THE PARTNERSHIP

II

DESIGN INSPIRATION

From a creative partnership to design inspiration. From the first stroke of a pencil through hundreds of iterations. A timepiece like no other comes to life. Shaped like a hypercar. Designed for elation. Transparent to the highest degree.

III

THE DEVELOPMENT PROCESS

Case crafted out of solid transparent sapphire crystal. 578 components. One-minute flying tourbillon with 30° incline. W16 engine-block automaton. 60-hour power reserve.

IIII

THE COMPLICATIONS AND FEATURES

IofIIII

THE ENGINE BLOCK AUTOMATON

Jacob & Co. revisited the ancient tradition of automata with a W16 engine block animation. The large single block of transparent sapphire recreates the layout of the famed W16 Bugatti engine. At the press of a button, its 16 pistons fire up and down in their sapphire cylinders, driven by a single-block crankshaft. During the 15-second animation sequence, the Bugatti Chiron Tourbillon Sapphire Crystal comes to life.

IIofIIII

THE 30° FLYING TOURBILLON

The Bugatti Chiron Sapphire Crystal’s tourbillon offers enhanced accuracy and a cinematic experience. Especially because it's tilted by 30 degrees. This incline increases the beneficial effects of the tourbillon. Its front-end location and the absence of an upper bridge, which makes it a flying tourbillon, enhance its unique presence.

IIIofIIII

THE POWER RESERVE INDICATOR

The Bugatti Chiron Tourbillon Sapphire Crystal has a 60-hour power reserve. Such autonomy is an achievement at that level of high complication. A large barrel provides a steady stream of energy, whose level is indicated by a fuel gauge-type indicator.

IIIIofIIII

THE CROWNS

The Bugatti Chiron Tourbillon Sapphire Crystal follows one of Jacob & Co.'s design principles, which is not to use side crowns. Instead, it has three separate ones, located on the 6 o'clock flank of the case. The left crown sets the time on the central hour and minute dial. The center crown winds the movement clockwise, and the automaton counterclockwise. The right crown activates the W16 engine-block animation.

V

THE LIFESTYLE

VI

THE SPECIFICATIONS

BUGATTI CHIRON TOURBILLON SAPPHIRE CRYSTAL

Clear

I of VI